Inhaltsübersicht

- 1 Process safety in production: the controllability of hazards and processes

- 2 Definition of process reliability

- 3 Advantages of high process reliability

- 4 Difference between occupational safety and process safety

- 5 How process reliability is established in the company – step by step

- 6 Process reliability and digitalization – what can that look like?

- 7 More safety in all processes: Worker assistance helps!

- 8 The tepcon instructor secures your production processes

Process safety in production: the controllability of hazards and processes

Disruptions in day-to-day operations cost time and money, jeopardize production deadlines or pose a risk to people and systems.

In a world in which products are becoming increasingly individualized and requirements more complex, it is more important than ever to master processes reliably.

Process safety not only means protecting people, machines and the environment – it is also the basis for economical, stable and high-quality production.

We will show you how you can use digital tools, in particular our worker assistance systems, to increase your process reliability in a targeted manner and boost efficiency at the same time.

Definition of process reliability

By process safety, we mean the ability to design and operate industrial processes in such a way that they are controlled, reproducible and free from unwanted deviations. This involves safe process management – regardless of the type of product or the characteristics of the production environment.

Process reliability means that all key settings, steps and measures are clearly defined, documented and comprehensible to people – even in the event of an error.

Advantages of high process reliability

A high level of process reliability brings with it a whole range of benefits: it minimizes risks, reduces sources of error and ensures consistently high quality.

It also protects people and machines, optimizes the use of resources and reduces costs in the long term. Processes become more efficient, transparent and traceable – a decisive competitive advantage.

Last but not least, reliable production also fulfills regulatory requirements and environmental regulations.

Difference between occupational safety and process safety

Although they pursue different objectives, occupational safety and process safety are often confused in companies.

Occupational safety protects people from accidents and damage to health – for example through organizational measures or protective clothing.

Process safety, on the other hand, refers to technical procedures and processes to ensure the flawless manufacture of a product.

Both are about safety, but the perspective is different: Occupational safety is about protecting the employee, while process safety is about the quality and reliability of the product.

Both security measures are crucial for the success of a company and must be individually adapted depending on the type of process.

Are you in a hurry? Click here to go directly to our product, the tepcon instructor!

How process reliability is established in the company – step by step

The concept is clear, the concrete implementation follows in the next step: process safety requires a whole range of procedures that are very individual for each process and in each company. Essentially, however, several steps can be identified that serve as a framework for defining the appropriate method.

- Analysis of the current process profile: First, existing processes, risks and weaknesses must be systematically analyzed.

- Requirements definition: Requirements for processes, machines, data and programs are developed on the basis of this information.

- Introduction of standardized procedures: Clear procedures and defined settings allow processes to be stabilized and made repeatable.

- Employee involvement and training: People are key players in production. Measures can only be implemented effectively if they understand the values, objectives and safety considerations.

- Continuous monitoring: Digital programs are used to ensure the determinism of the processes and intervene automatically if necessary.

Process reliability and digitalization – what can that look like?

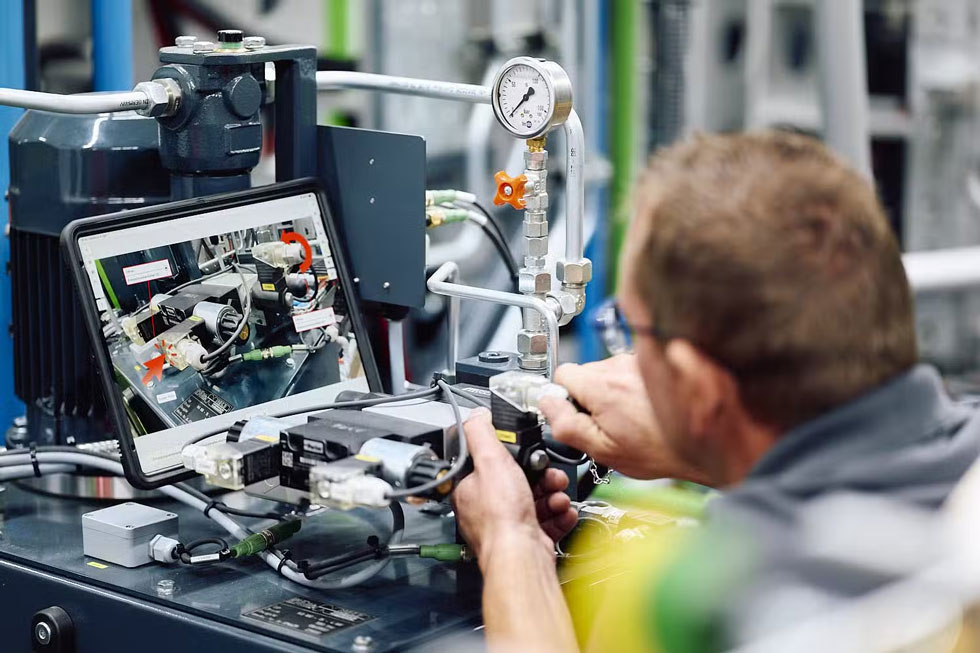

Digitalization opens up completely new possibilities for achieving process reliability. Intelligent programs record data in real time, analyze deviations and ensure that processes follow the desired sequences exactly.

Digital information is always available exactly where it is needed – and helps to achieve consistently high-quality results.

More safety in all processes: Worker assistance helps!

Worker assistance systems are an effective digital tool for increasing process reliability. They ensure that every work step is carried out correctly, completely and in the right order – regardless of the employees’ level of experience.

Digital work instructions guide you through all process steps, provide additional information if required and prevent typical errors – they are highly safe and reliable.

In production, they create more safety, improve traceability and increase quality. This makes processes safer, relieves people and optimizes results.

With tepcon “instructor”, our worker assistance software, you create a strong foundation for safe, efficient and future-proof production.

Click here to go directly to the personal contact!

The tepcon instructor secures your production processes

We have stood for expertise in innovative digitization solutions since 2002.

With digital work instructions and worker guidance via tepcon “instructor”, you can raise process reliability in your company to a new level.

Rely on our expertise and find out more about the “instructor” in a personal meeting now.