Inhaltsübersicht

- 1 Digitizing business processes: the ultimate guide to successful implementation

- 2 The most important facts at a glance

- 3 Process digitization: How to make the change a success

- 4 The most important steps for digitizing business processes

- 5 Successful implementation of digital business processes

- 6 Employee training and change management

- 7 Monitoring and continuous improvement

- 8 The tepcon instructor: The solution for anyone who wants to digitize business processes

- 9 Where can business processes be digitized here?

- 10 Frequently asked questions

Digitizing business processes: the ultimate guide to successful implementation

Change is underway across all sectors and company sizes:

There has long been no alternative to the digitalization of business processes. However, the possibilities and potential have not yet arrived everywhere. Digital processes can increase the efficiency of your own business, as digital systems reduce the error rate and save time and money.

What steps and technologies play a role in this and how can the tepcon instructor help? You will find answers to these questions in this text.

The most important facts at a glance

- The digitalization of business processes increases efficiency, reduces costs and improves competitiveness through automated workflows.

- A structured approach, including as-is analysis, target definition and technology selection, is the key to the success of any digitalization strategy.

- Core processes such as customer service and contract management, but also production, are particularly well suited to digitalization: Significant benefits can often be achieved here.

Process digitization: How to make the change a success

Process digitization in the corporate sector is playing its part in ensuring that companies can continue to cope with the growing range of technologies and the dynamic market around the globe.

Industry 4.0 demands creative, flexible, fast and customer-oriented working methods in all areas. Digitized processes are a good way to cope with this – but traditional paperwork is not. Today, economic success and competitiveness also depend on whether and how thoroughly your company’s processes have been examined for their digital potential.

A key advantage of digitalization is the improvement in flexibility and agility, as manual processes are avoided. By converting analogue workflows into digital processes, companies not only save time and costs, but also optimize their workflows. Data can be archived automatically and the document management system ensures simple, less personnel-intensive administration with maximum efficiency.

The data collected by the software can also be put to good use: They reveal optimization potential, for example with the analysis of usage and waiting times. Thanks to the digital management of their processes, companies need to invest less time and effort in tracking, measuring and adapting, thanks to automation. In the long term, optimized company processes not only improve the organization in all departments, they also have the potential to sustainably increase overall competitiveness.

What are the benefits of process optimization?

The digitalization of business processes means using digital technologies to transfer analogue to digital processes. This change brings with it numerous advantages:

- Cost savings

- Productivity increase

- Efficiency improvement

- Better data analysis

- Increased flexibility

Digital business processes ensure optimized workflows: A digital business process can generally be implemented faster in terms of time and money than the analogue route. This increases productivity and employees can be assigned other tasks for which valuable time was previously lost.

Hidden resources in the general organization and in all areas of the company can be exploited with digitalized processes. If you don’t want to be overtaken by the competition, there is no way around digital business processes.

So let’s take a detailed look at the path that leads to process digitization. From the analysis of the current situation to the definition of target goals and the selection of suitable technologies – get an overview of the possibilities and opportunities to ensure your success with digitalized workflows.

Want to find out more about digital business processes?

Which business processes are best suited for digitization?

Not all business processes are equally suitable for digitization. But thanks to modern technologies and software, a surprisingly large number are. Typical candidates for process digitization would be customer service, contract management and sales, for example. Here, the digital solution often has a direct positive impact on customer relationships and, as a result, on business success.

In the administrative area in particular, almost all business processes can be digitized if they have not already been. With the aim of increasing efficiency and saving resources, it is worth taking a look at existing process steps in accounting, human resources and purchasing. If companies digitize work processes in these areas, they can optimize old workflows and improve the efficiency of their entire organization.

Common challenges and solutions in process digitization

Cost-benefit analyses help companies to assess the actual potential of their digitalization projects. Rising costs are a common challenge when digitizing processes. A comprehensive security strategy is necessary to address security concerns related to data protection and cyberattacks.

Digitalized processes can be inefficient and impair company growth. Digitization itself does not automatically lead to an increase in process quality.

Companies need holistic solutions for successful digitalization. Read below to find out how. Or book your consultation directly for your individual, customized solution with the tepcon instrucotor.

The most important steps for digitizing business processes

The digitalization of business processes enables companies to be faster, more flexible and more customer-oriented while reducing costs. For this project to succeed, a clear digitalization strategy is required that takes into account the specific requirements of the company.

Ideally, you should examine the individual areas and processes as part of the digitalization process. You should proceed step by step and not want to revolutionize everything in one fell swoop: With a well-planned transition, you will not overwhelm your employees and will be able to review and convert all process steps with due attention in the long term.

A classic process model for digitalization includes analysis, target definition and selection of technologies. This structured approach is the basis for successful process digitalization.

Digitize business processes in three steps – this is how it works

Digitizing business processes can be a major challenge in some organizations and companies. The integration of new systems into existing structures is often demanding and time-consuming, depending on the area. It is also important to take this into account: Uncertainties about legal requirements can delay the implementation of digitization.

In view of the potential pitfalls, step one of process digitization is all the more important.

Step 1: Analysis of the current business processes

FMEA risk management is another important approach to error prevention. The FMEA method supports preventive quality assurance by systematically identifying and prioritizing the causes of errors and potential defects in the production process.

FMEA analysis is a structured process consisting of seven steps:

The aim of the as-is analysis is to create a digitalization strategy.

The following steps should be observed in order to carry out the ACTUAL analysis:

- Summarize and collect all processes.

- Document detailed procedures of existing processes.

- Consider both manual and inefficient processes.

- Include documented process sequences.

These steps help to create a comprehensive basis for the digitalization strategy.

The ACTUAL analysis determines the qualitative and quantitative ACTUAL status of the business processes. It serves to evaluate the efficiency of existing processes and identify potential for improvement. This inventory can then be used to create a ranking list of the business processes to be digitalized.

Step 2: Set target goals for digitization

The following points should be taken into account when defining the goals for digitalization:

- exact requirements

- Time frame

- persons involved

- Cost framework

- suitable software

The current degree of digitization of processes can be evaluated using a standardized scheme for classifying business processes.

The following factors are used to determine the digitization potential of the business processes: possible cost and time savings, frequency of the processes and any existing psychological pressure in the departments examined.

In order to carry out an effective cost-benefit analysis of digitalization, questions should be asked about the costs of digitalization and the resulting benefits. After digitization, it should be checked whether the processes have reached the desired target state and whether there is further potential for improvement.

Step 3: Selection of suitable technologies and tools

The selection of technologies for process digitization should be based on specific requirements and long-term flexibility. Process management tools and automation solutions are crucial for the successful digitalization and optimization of business processes. Tools should meet current requirements and be future-proof.

Suitable technologies for the digitalization of business processes include

- Process management tools

- CRM software

- Cloud platforms

- Automation tools

Document management systems (DMS) play an important role in the electronic storage, management and tracking of documents.

Successful implementation of digital business processes

Once the process is complete, digitalization ideally has the following effects on business processes:

- Higher efficiency

- Better margins

- Lower costs

- More transparency

The entire company benefits financially from digitization through time savings, which leads to cost reductions and sometimes also saves on personnel deployment.

Employee training and change management

Training is crucial for the success of the implementation and employee acceptance. To digitize your business processes, you need every single team member to be involved in optimized workflows.

The employees concerned need suitable training so that they can use new technologies effectively and solve problems. Under certain circumstances, routine tasks can be digitized independently by employees, for example with suitable low-code tools.

The active participation of all employees in digitalization not only promotes new ideas, but also strengthens their commitment and motivation. The necessary change management requires a comprehensive strategy for planning and developing changes. A flexible division of labor between user groups can increase acceptance of the change project.

Want to find out more about digital business processes?

Monitoring and continuous improvement

Once the initial process is largely complete, the next stage follows: monitoring and further optimization.

Monitoring digital processes is important to ensure that the desired results are achieved. It is necessary to review the digital processes on a regular basis: Are the desired goals still being achieved, are any adjustments to the process necessary?

These factors can be used to measure whether the digitalization of business processes is successful:

- Target achievement

- Expenditure

- Transparency

- Error avoidance

Continuously reviewed, expanded and adapted, digital processes ensure flexibility and adaptability in all areas of the company.

The tepcon instructor: The solution for anyone who wants to digitize business processes

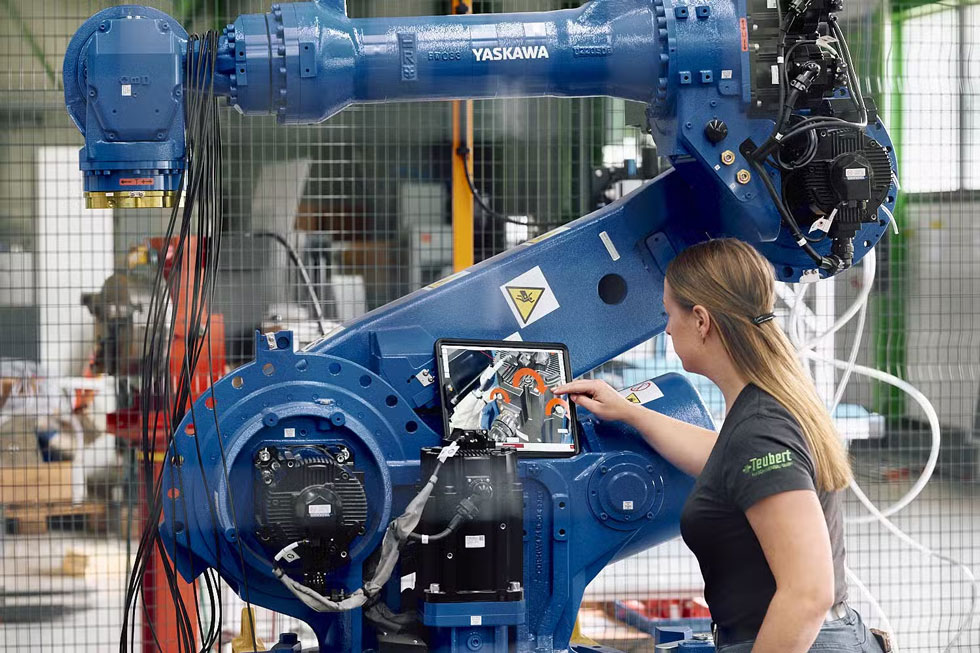

Let’s take a concrete look at where and how business processes have been successfully digitized. In industrial production, which has been modernized with Internet of Things (IoT) technologies, there are countless possible applications, for example for software that can be used to explain and accompany a process for inexperienced users.

Digital work instructions, service documentation and assembly instructions make daily work easier in many companies today. They provide instant access to up-to-date and interactive information – anyone who needs it can access the necessary data immediately.

This is the solution offered by our tepcon instructor: Digital work instructions can be created within minutes using this software. It’s no secret that efficient assembly and service instructions are the basic prerequisite for production to flourish.

Our success story from the mechanical engineering sector shows the concrete impact of this. We were able to help a specialist for processes in microchip production with our software for in-process documentation and guidance.

Our customer, a renowned manufacturer of special machines in the semiconductor industry, operates in a rapidly growing and very complex sector. This makes it all the more important to react professionally, quickly and flexibly to the constantly emerging challenges of the market.

Concrete support was required, as the construction time of systems should be as short as possible so that capacities can be optimally utilized to increase production volumes.

The three steps mentioned above – analysis – optimization – review – were also followed in this case.

Where can business processes be digitized here?

The team found what they were looking for when it came to documenting work processes and creating work and assembly instructions. They were still working with Word documents and Power Points, which was not very standardized and extremely cumbersome to create. Mobile access to the instructions was also not available everywhere; sometimes they were even printed out on paper.

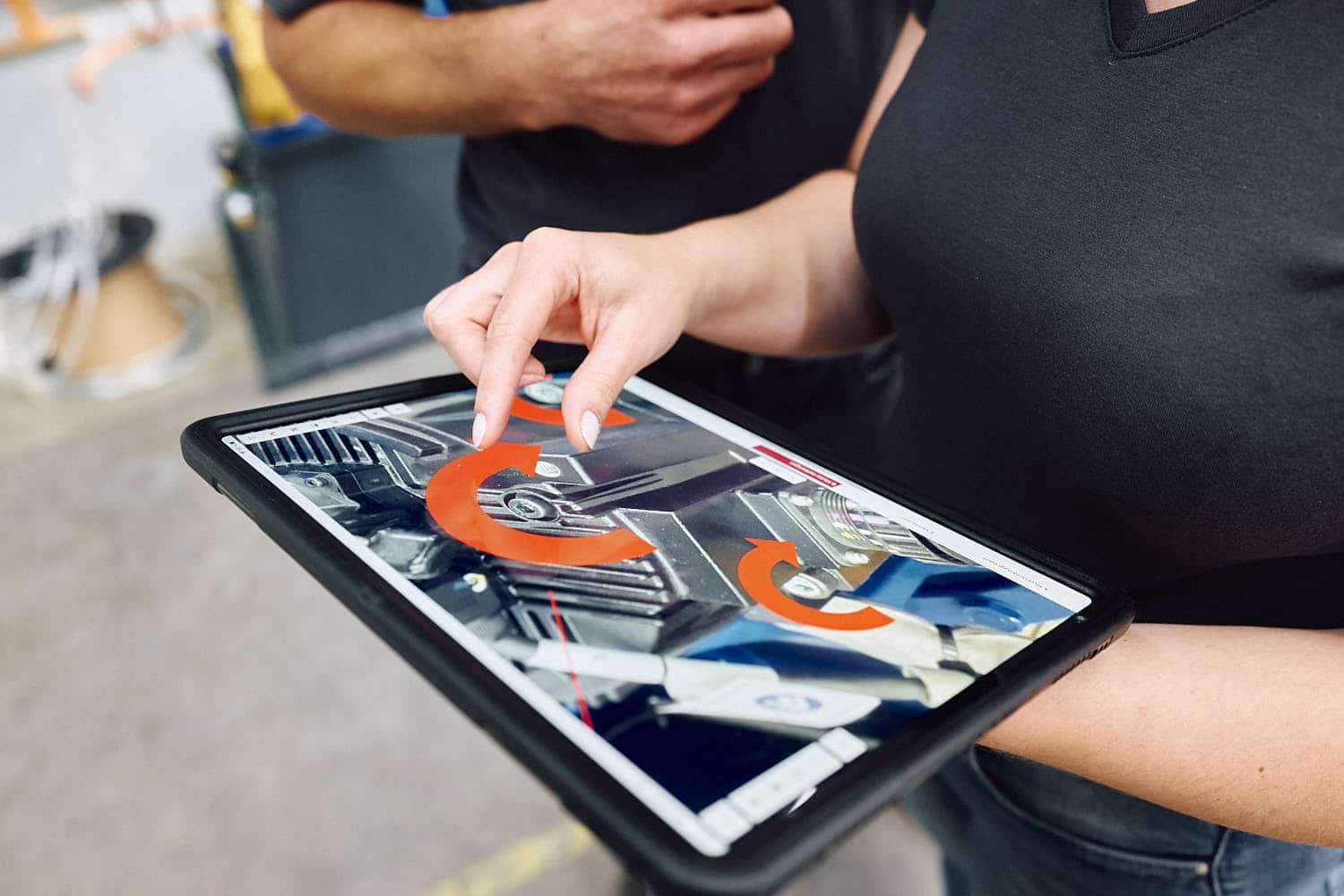

In step 2, the optimization process, we planned an optimization project with the help of the tepcon instructor. This has several advantages: the necessary work and assembly instructions can be created easily and in a standardized way. All information is available at lightning speed on all end devices and can also be read directly at the workplace using a QR code. The low-code solution simplifies the creation process, as instructions can be created using symbols and color coding.

Because each manual can be customized, it is geared to the employees’ level of knowledge. In addition, each user simply selects the information that corresponds to their level of knowledge.

The instructor enables a reliable release process and versioning. Adjustments can therefore be made easily at all levels if required.

The review, the third step, showed the success of this optimization process.

Expressed in figures: the construction time of a special machine was reduced by more than 50%. As a result of the time saved, the output quantity was more than doubled. Despite the impressive increase in production, further qualitative progress was also demonstrated: With a 30% reduction in the time required for reworking at the customer’s premises, the customer achieved a significant increase in quality.

At the same time, the tepcon instructor increased transparency across the entire process chain. The standardized, seamless and easily accessible documentation and logging of work processes forms the basis for a continuous optimization process.

Do you want to digitize your business processes and write your own success story? Then book your consultation here!

Digitizing business processes made easy: with tepcon at your side

The digitalization of business processes is a decisive step for the efficiency, productivity and competitiveness of a company. Companies can successfully digitalize their processes through a structured approach, starting with an analysis of the current situation and the definition of target objectives through to the selection of suitable technologies and tools.

The successful implementation of digital business processes also requires comprehensive employee training and effective change management. Through continuous monitoring and improvement, companies can ensure that their digital processes function optimally and deliver the desired added value. You can master the challenges of digitalization with a clear strategy and careful planning.

We are at your side for all these challenges. With a concept optimally tailored to your company that tackles process digitization step by step. We not only have extensive experience and a mature product for basic digitalization: Our expert consultants will accompany you from the actual transformation to employee training and subsequent optimization.

We are your partner for innovative digitalization solutions for industry & services. Contact customer service directly!